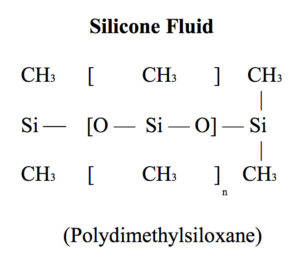

Silicones: Unique Chemical Structure

Unique Properties and Characteristics of Silicones

This chemical structure gives silicone fluids a profile of properties, which permits them to perform in applications where other fluids would not be suitable. Some of the outstanding properties shared by most silicone fluids are;

- Low‐Viscosity‐Temperature Change: All fluids show some degree of change in viscosity with temperature change, but silicone fluids exhibit a much smaller degree of change over a wider temperature range than non‐silicone fluids.

- Wide Temperature Range: Low temperature limits and high temperature capabilities of silicone fluids far surpass those of conventional fluids.

- Thermal Stability: Silicone fluids show excellent stability when exposed to high temperatures for extended periods of time. (See also # 16 below)

- Thermal Conductivity: The thermal conductivity of silicone fluids over a wide temperature range is comparable to hydrocarbon fluids.

- Chemical Inertness: Silicone fluids are chemically inert to most common materials of construction.

- Low Flammability: Flash points in the range of 205ºC to 260ºC (400ºF to 500ºF) and auto‐ignition temperatures in the range of 438C to 460C (820ºF to 860ºF) are typical for silicone fluids. Low Surface Tension Silicone fluids have unusually low surface tensions, which help provide easy and efficient spreading, high surface activity and low internal cohesive energies. Lower viscosities provide lower surface tensions than higher viscosities.

- Compressibility: Silicone fluids of 10 centistokes or more exhibit compressibility of 1.34% at pressures of 2,000 psi at room temperature. Lower viscosities exhibit higher compressibility than higher viscosities.

- Non‐Corrosive: Silicone fluids contain no acid producing chemicals to cause staining or corrosion.

- Low Surface Tension: Silicone fluids have unusually low surface tensions, which help provide easy and efficient spreading, high surface activity and low internal cohesive energies. Lower viscosities provide lower surface tensions than higher viscosities.

- Shear Stability: Silicone fluids have unusually high resistance to breakdown by mechanical shearing. The shear stability of silicone fluids can be as much as twenty times that of quality petroleum oils, providing longer life at higher speeds and loadings.

- Shear Characteristics: The viscosity of a fluid is defined as the ratio of shear stress to shear rate. In the ideal, or Newtonian fluid, this ratio is constant and is independent of the shear rate. In a non‐ Newtonian fluid, the ratio is not constant and the apparent viscosity at high shear rates is less than the true viscosity. The dimethyl fluids (Pure Silicone Fluids) approach Newtonian behavior. The lower the viscosity, the more nearly Newtonian the fluid. The apparent lowering in viscosity or pseudo‐plastic flow at high shear rates of dimethyl silicones is a transitory condition as the fluids will return to their original nominal viscosity on cessation of shear. Many organic fluids show a drop in nominal viscosity after prolonged shearing action. This is a permanent loss in viscosity resulting from poor shear stability and is different from the recoverable drop in viscosity demonstrated by silicone fluids. The permanent viscosity change results from the molecules being torn apart by the mechanical action. Silicones show extremely good shear stability and retain their original viscosity characteristics as they are not affected by mechanical working

- Dielectric Properties: Electrical grade silicone fluids offer excellent dielectric properties, which are maintained for prolonged periods, even under adverse operating conditions. (Note Clearco’s STO‐50 electrical grade fluid is a dimethyl silicone fluid processed to provide outstanding dielectric properties. Because of the basic properties of silicone fluids, these electrical properties are maintained for prolonged periods and under adverse operating conditions).

- Weight Loss at Atmospheric Pressure: The weight loss of silicone fluids is determined in a forced air‐circulating oven at atmospheric pressure. The dimethyl fluids are conventionally measured after exposure at 150ºC (302ºF) for 24 hours. Phenyl fluids, such as PM‐125 & PPM‐500, may also be measured by this test, although higher temperatures are frequently employed. At very high temperatures, the loss in simple volatiles is compounded by some oxidative effects.

- Specific Heat: Specific heat of most silicone fluids falls in the 0.36 to 0.39 BTU/lb./F range at room temperature.

- Lubrication Properties: The dimethyl, methyl alkyl and phenyl fluids are outstanding lubricants suitable for many severe applications at temperatures from –73ºC to 232ºC (‐100F to 450F). The dimethyl and phenyl silicone fluids are generally not recommended as metal‐to‐metal lubricants. They lack the lubricity required for most mechanical applications involving sliding friction, although phenyls possess better metal‐to‐metal lubricity than dimethyls. On the other hand, dimethyl fluids are the best lubricants in rubber or plastic‐to‐metal applications.

- Oxidation Stability: The oxidation stability of silicone fluids is excellent. Absence of copper‐induced oxidation is especially important and contrasts with the sludging that occurs with mineral oils, especially at high temperatures. In the presence of air, oxidation stability becomes an important factor in the high temperature performance of silicone fluids. In oxidative break‐down, oxygen reacts with the organic groups of the molecules causing fluids to lose volatiles and increase in viscosity until gelation occurs. The reaction is dependent on the temperature and supply of air. Oxidation Threshold Oxidation Threshold is defined as the temperature at which a significant amount of oxidation by‐products start to appear. Below this temperature, some oxidation will occur which will not adversely affect the useful life of the silicone fluids. The following table compares the Oxidation Threshold of several silicone and organic fluids. This information is offered for comparison purposes only with the suggestion that user perform his own appropriate tests.

Fluid Oxidation Threshold, Temp °C (°F) PM‐125 271 (520) PSF Fluids (+100cSt) 204 (400) Dibasic Acid Ester 66 (150) Petroleum Oil 66 (150) - Thermal Stability: In the absence of air, silicone fluids show excellent stability when exposed to high temperatures for long periods of time. In sealed systems or in an inert atmosphere, such as nitrogen or carbon dioxide, high temperatures above their thermal activation points can break the bonds linking silicon and oxygen in the silicone fluid to form lower molecular weight volatile silicones. The activation point for dimethyl fluids is about 316C (600F), and for phenyl‐containing fluids it is slightly higher. The useful life of silicone fluids under non‐oxidative conditions below their thermal activation points continues for many hundreds of hours.

Fluid 149°C (300°F) 204°C (400°F) 232°C (450°F) 260°C (500°F) PSF-100cSt Approx 1-year 250 to 300 40 to 60 hours 20 to 25 hours PSF-1,000cSt Approx 1-year 175 to 225 20 to 30 <15 PSF-10,000cSt Approx 1‐year 100 to 120 15 to 20 <10 The degradation products that form at or near the thermal activation temperature are completely compatible with the base polymer. In a sealed system, a decrease in overall nominal viscosity is usually experienced when thermal degradation produces low molecular weight fractions, which lower the average molecular weight of the silicone fluid. An increase in vapor pressure in sealed systems results from the formation of volatile silicones.

All of these properties are found in the basic family of dimethyl silicone fluids, which are available in a wide range of viscosities.

* Note: To meet specific application needs, Clearco provides a wide variety of silicone fluids.

Hundreds of Silicone Fluid Applications in almost every Industry

- Damping Fluids (Meets VV‐D‐1078) Aircraft Instruments, Dashpots, Gyros, Meters, Shock Absorbers, Time Delay Relays, Timing Devices, Torsional Vibration Dampers, Diff Oils for motorized cars

- Thermal Bath Fluids (open and closed systems) High temperature baths, Low temperature baths, Heaters/Chillers

- Power Transmission Controlled Speed Devices, Fluid Clutches, Hydraulic Systems

- Heat Transfer Heating Baths, Heat Exchangers, Low Temperature Baths, Thermostats

- Liquid Springs and Shock Absorbers Missile Suspension Systems, Railroad Cars, Trucks

- Polishes Boat Polish, Car Polish, Furniture Polish, Metal Cleaners, Vinyl Polish, Window Cleaners

- Cosmetics and Pharmaceuticals Anti Perspirants, Deodorants, Hand Creams and Lotions, Hair Sprays, Lipstick, Make‐up or Color Cosmetics, Process Aids for Anti- biotic Preparations, Shampoos and Conditioners, Shaving Creams, Sterilization Baths, Treatment of Vials and Syringes

- Rust Prevention Decorative Ware, Gun Oils, Metal Cleaners

- Calibration Fluids Flow tests, Calibration tests, Process flow modeling

- High Shear Applications

- Hydraulic Fluids Constant Speed Devices, Engine Controls, High Temperature Plastic Forming, Missile and Space, Vehicles Systems, Naval Hydraulics Systems, Supersonic Aircraft

- Dielectric Fluid Capacitors, Klystrons, Magnetrons, Microwave Tubes, Power Rectifiers, Radar Equipment, Transformers (STO‐50)

- Release Agents Automobile and Truck Tires, Fan Belts. Molding, Ingot Mold Wash, Plastics, Rubber Mats, Shell Mold and Core Molding, Shoe Heels and Soles, Wire and Cable Slip Agent

- Water Repellents Textile, Underarm Dress Shield

- Antifoams Aromatic Scrubbing, Asphalt High Detergent Motor Oils, Petroleum Defoamers

- Paint and Coating Additives Defoaming Natural Gum and Synthetic Resin, Varnishes, Elimination of Blocking High Gloss Paints, Improved Pigment, Dispersion, Improved Slip or Release Characteristics

- Lubricants Base Fluids for Greases, O‐Ring lubricant, Rubber and Plastic Parts, Plastic‐to‐plastic, Plastic‐to‐metal, Plastic‐to‐foam, Lubrication, Gasket lubricant, Valve lubricant

- Textile Finishing Thread Lubes, Softeners, Water Repellants

- Anti‐blocking Agents Paper Sheet, Plastic Sheet, Rubber, Wax Cartons for Foods

- EDM Coolants

- Food Packaging Anti‐blocking, Dry Foods Meats, Paper Plates, Lubricant for foam and saran, Prevents sugar build‐ ups

- Food Processing Antifoaming, Dry Food Release

- Particle Treatments Dyes, Fillers, Fire Extinguisher, Particles, Pigments

- Rubber and Plastic Additives Elimination of Blocking, Extrusion Aids, Internal Release Agents, Plasticizers

- Photography Projector Lubricant Repair, Scratched Negatives

- Gas Chromatography Stationary Phase

Specific Products: Description and Selection

Clearco Silicones offers a complete line of silicone fluids in a wide viscosity range to provide maximum latitude in selecting the specific silicone fluid to meet the requirements of a particular industrial, military or consumer application.

While it is difficult to recommend the use of any one fluid for an application, this publication lists various applications and indicates the Clearco silicone fluids most frequently used. Generally speaking, it is best to evaluate several possible silicone fluids to determine which will provide the optimum performance in an application.

Listed below are descriptions of the commonly used Clearco silicone fluids with examples of the types of applications for which the fluids are designed.

- Food Grade Silicone Fluid Clearco PSF‐350cSt is registered with the NSF/USDA as an H1 lubricant for incidental contact in food processing and food packaging applications.

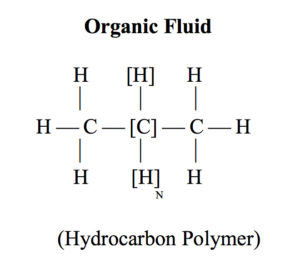

- DIMETHYLS (Polydimethylsiloxanes / PDMS Silicone Oils)

- Super High Viscosity Pure Silicone Fluids Clearco Pure Silicone Fluids are Polydimethylsiloxane Fluids / PDMS Silicone Oils. They are clear, oily fluids; inert, tasteless, and odorless. PSF fluids are available in the viscosity range from 0.65 to 2.5 million cSt. (Viscosities measured at 25C /77F). The actual viscosity is controlled within ±5 percent of the nominal viscosity in the grades of 50 centistokes or higher. The unique combination of properties associated with the PSF fluids makes them suitable for plastic and rubber lubrication, as dampening or heat transfer fluids, as thermal bath fluids, high shear fluids, dielectric applications, and as an oil defoamer. These fluids are also used in chemical specialties, antifoams, paint additives and other similar applications. Low Viscosity Fluids (0.65cSt to 20cSt)

- Low Viscosity Pure Silicone Fluids They are characterized by low molecular weights, low surface tension, volatility (viscosities below 5cSt), high compressibility and excellent low temperature performance. They are often used as base fluids in a wide array of cosmetic ingredients. Other applications include damping applications and low temperature bath fluids.

- High Viscosity Pure Silicone Fluids Hi‐Viscosity Silicone Fluids are clear, colorless, & Odorless PDMS Silicone Oils / Polydimethylsiloxane fluids with no suspended particulate matter. They are inert, tasteless and odorless. The Hi‐Viscosity fluids are available in standard viscosity grades of 5,000, 10,000, 12,500, 30,000, 60,000, 100,000, 300,000, 600,000, 1million and 2million cSt @ 25C (77F). Hi‐Viscosity fluids are characterized by relatively small changes in viscosity over a wide temperature range. They have good oxidative stability, high chemical inertness and resistance to breakdown under mechanical shearing. Hi‐Viscosity fluids are especially useful for linear and torsional dampeners, viscous drive clutches, speed control devices, liquid springs, dash pots, rubber and plastic lubricants, timing devices, and are the base fluids for silicone compounds.

- Medium Viscosity Pure Silicone Fluids Like the Low and High viscosities, the Standard viscosities are 100$ PDMS Silicone Oils / Polydimethylsiloxane Fluids that offer a wide range of thermal stability, high resistance to shear, high oxidative resistance, and low viscosity change from temperature. They are excellent fluids to be used in damping, shearing and thermal applications.

- PSF‐350cSt Pure Silicone Fluid NSF H1 Food Grade PSF‐350cSt (food grade) is a clear, colorless and odorless Polydimethylsiloxane / PDMS Silicone Oil with a viscosity of 350cSt @ 25C. The PSF‐ 350cSt is registered with the NSF/USDSA as an H1 lubricant for use in food processing and food packaging applications where incidental contact with food may occur. It is also approved as an antifoam agents contributing no more than 10 ppm of the fluid to food, other than milk and articles intended for the feeding of infants and invalids.

- STO‐50 Silicone Transformer Oil Chemically, the STO‐50 fluid is identical to the PSF fluids, but has been specially processed and controlled to meet electrical grade specifications. It has a viscosity of 50 centistokes fluid at 25C (77F). The actual viscosity is controlled within ±5 percent of the nominal viscosity. The unique properties of STO‐ 50 electrical grade silicone fluid extend its capabilities beyond those of conventional dielectric fluids. This makes the fluid suitable for use in capacitors, pulse transformers, specialty transformers, air‐borne and land based radar equipment, television circuit components and in systems where heat transfer properties are as necessary as dielectric behavior.

- PHENYLS Extreme Temperature Fluids – Even greater high‐temperature resistance has been added by the incorporation of phenyl groups in the silicone molecule. By replacing methyl groups with phenyl groups, temperature stability is increased to 250C (open system) and short periods at 300C.

- PM‐125 Phenylmethyl Silicone PM‐125 is a hi‐content phenylmethyl silicone that is a clear, light straw colored liquid which possesses significantly better heat stability than conventional PDMS Silicone Oils. This outstanding heat resistance is combined with low volatility and high flash point to provide a normal useful service temperature range of ‐ 25ºC to 250ºC. PM‐125 is an excellent choice for high temperature heat transfer applications or as a base fluid in high temperature greases. In comparison to PDMS Silicone Oils / dimethyl silicones, it also exhibits better lubricity for metal‐to‐metal applications, higher resistance to oxidative attack, and a higher refractive index for optical applications.

- PPM‐500 (100% Phenlmethyl Silicone) PPM‐500 is a 100% phenylmethyl silicone that possesses the highest thermal stability. With 100% phenyl content, it has a higher Refractive Index of 1.533 for optical applications.

- Phenyl Silicone Applications include: high temperature bath fluids, dielectric coolants for high temperature ultra‐sonic coupler, high temperature heat bath and oxide protector for solder baths, hydraulic arrestors, valves and instruments in nuclear power plants.

- COSMETIC GRADE SILICONES Clearco Polydimethylsiloxane Fluids are classified under INCI (International Nomenclature for Cosmetic Ingredients) as Diemthicones and are used in a variety of skin creams, gels, hair conditioners and other personal care products.

- Cyclomethicones (Volatile Cyclic Silicones) Cyclo‐2244 (D4), Cyclo‐2245 (D5) & Cyclo‐2345 (D5/D6 blend) Cyclomethicones are unmodified silicones that possess a cyclical structure rather than the chain structures of dimethyl silicones. Low heat of vaporization and the ability to select a desired vapor pressure has led their use as cosmetic vehicles Cyclo‐2244 fluid is primarily octamethyl‐ cyclotetrasiloxane (Tetramer) (D4) INCI Name: Cycotetrasiloxane

- Cyclo‐2245 fluid is primarily decamethyl‐ cyclopentasiloxane (D5) INCI Name: Cyclopentasiloxane Non‐polar and insoluble in water, these silicone fluids are completely miscible in the lower alcohols as well as in typical aliphatic, aromatic, and halogenated hydrocarbon solvents. Non‐polar and insoluble in water, these silicone fluids are completely miscible in the lower alcohols as well as in typical aliphatic, aromatic, and halogenated hydrocarbon solvents. Due to these properties, they are used as base fluids in a wide array of cosmetic products such as antiperspirants, deodorants, hair sprays, cleansing creams, skin creams, lotions and stick products, bath oils, suntan and shaving product, make‐up and nail products.

- Cyclomethicones also come under the classification of “Volatile Fluids”: For those applications where volatility is desirable, the volatile cyclics should be used. The PSF‐0.65cSt (hexamethyldisiloxane) is a linear silicone that exhibits similar volatility characteristics to the cyclomethicones.

- METHYL ALKYLS Outstanding Lubricants, “Paintable” Fluids Clearco Pure Paintable Silicone The MAPR‐L Paintable Silicone Fluid is used in lubricating, die cast and release applications. This fluid is useful in applications requiring paintability and in areas where prevention of secondary paint contamination should be avoided. MAPR‐L is also found useful as an internal mold release agent in vinyl slush molding applications, and as an aluminum die cast mold release agent.

- Silicone Grease (PDMS Silicone Compound) Clearco Silicone Grease 3005 (food grade) is an NLGI II grease‐like material containing pure polydimethyl silicone fluid and inert silica filler. It is used in a wide range of applications that require…good thermal stability, high dielectric strength, inertness, corrosion and moisture resistance, low odor, and areas that require good lubricating properties over long periods without drying out. Silicone Grease 3005 is compatible with virtually all O‐Ring and Valve materials, including: Aflas, Chemraz, Nitrile, Hydrogenated, Polyurethane, Styrene Butadene, Buna‐N (Nitrile), Natural Rubber, Polyurethane, Teflon, Butyl, and Neoprene.